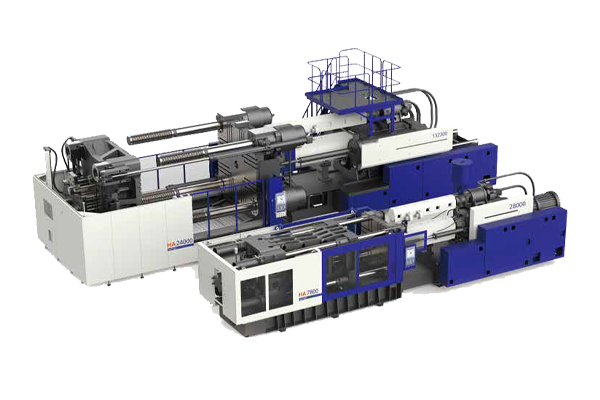

HA/AURIGA Series is a range of injection moulding machines offering innovative and special solutions for the extrusion injection moulding industry. It is designed to fulfil wide size and weight distribution requirements for products such as inspection wells, pipelines and filter plates in line with increasing environmental protection and infrastructure demands.

This series offers a wide range of models capable of producing products up to 500 kg. The injection moulding machines are equipped with different injection structures, which can be selected as high-pressure type or standard type. The two-stage injection structure, which provides superior injection stability and rigidity, offers excellent performance in large volume production.

The HA/AURIGA Series is also equipped with plasticised components with high wear resistance, suitable for working with recycling materials such as PE, PP and additives. The alloy screw barrel and wear-resistant screw structure with high mixing capacity ensure high productivity and quality even with difficult materials. It offers cost-effective solutions with features such as large injection volume, long cycles and multiple core pulling. Options such as piston blower, opening of the machine base under the mould and energy-saving heating improve performance and optimise production processes.

Plasticising with High Abrasion Resistance

Two Stage Injection Structure

Wide Product Size and Weight Range

High Pressure and Standard Type Options

Up to 500 kg Production Capacity

The HA/AURIGA Series is also equipped with plasticised components with high wear resistance, suitable for working with recycling materials such as PE, PP and additives.

We will do our best to get back to you as soon as possible after we receive your form.